BUILT TO LAST

How We Test Rollink Luggage for Durability

Rollink is committed to the highest quality standards, and every suitcase is tested to prove it. We rigorously test our foldable hard shell luggage in each production cycle using fully loaded conditions, 25kg for checked sizes and 15kg for carry-ons, to make sure every bag can handle real travel.

From handle lifts to wheel mileage, zipper pulls to impact drops, each case is built to stay strong through airports, cobblestone streets, overhead compartments, and years of use. Scroll down to see the exact durability tests we perform and why foldable doesn’t mean flimsy.

Real World Simulated Testing

Every test you see below is done with a fully packed suitcase loaded with 25kg to simulate real world travel conditions.

From wheel test and handle pulls to drop impacts, we prep each case like it’s heading to the airport and give it the full treatment.

Because testing an empty suitcase doesn’t prove anything.

Spinner Wheels Mileage Test

We don’t just spin the wheels and hope for the best. Each Rollink suitcase is strapped to a bumpy conveyor belt and rolled for 32 km, the equivalent of a long haul airport journey (with some cobblestone chaos simulation for good measure).

This durability test checks how well our double 360° spinner wheels handle real world wear, so your bag keeps gliding smoothly trip after trip.

Luggage Drop Test

Whether it’s dropped at the airport or takes a tumble down the stairs, Rollink is built to take the hit. We drop each loaded suitcase on all 8 corners from a height of 60 cm, not once, but three times, to test impact resistance and overall durability.

Because what good is a suitcase if it falls apart the first time you do? We also threw it down some stairs several times for good measure.

Tumble Test

Baggage gets thrown, flipped, and mangled in transit, so we test for that too.

To simulate the chaos of travel, we load each suitcase with 25kg and send it through a rotating drum filled with hard obstacles. It’s slammed, spun, and knocked around for 25 full cycles to test structural integrity and shock resistance.

If it survives the tumble test, it’s ready for anything.

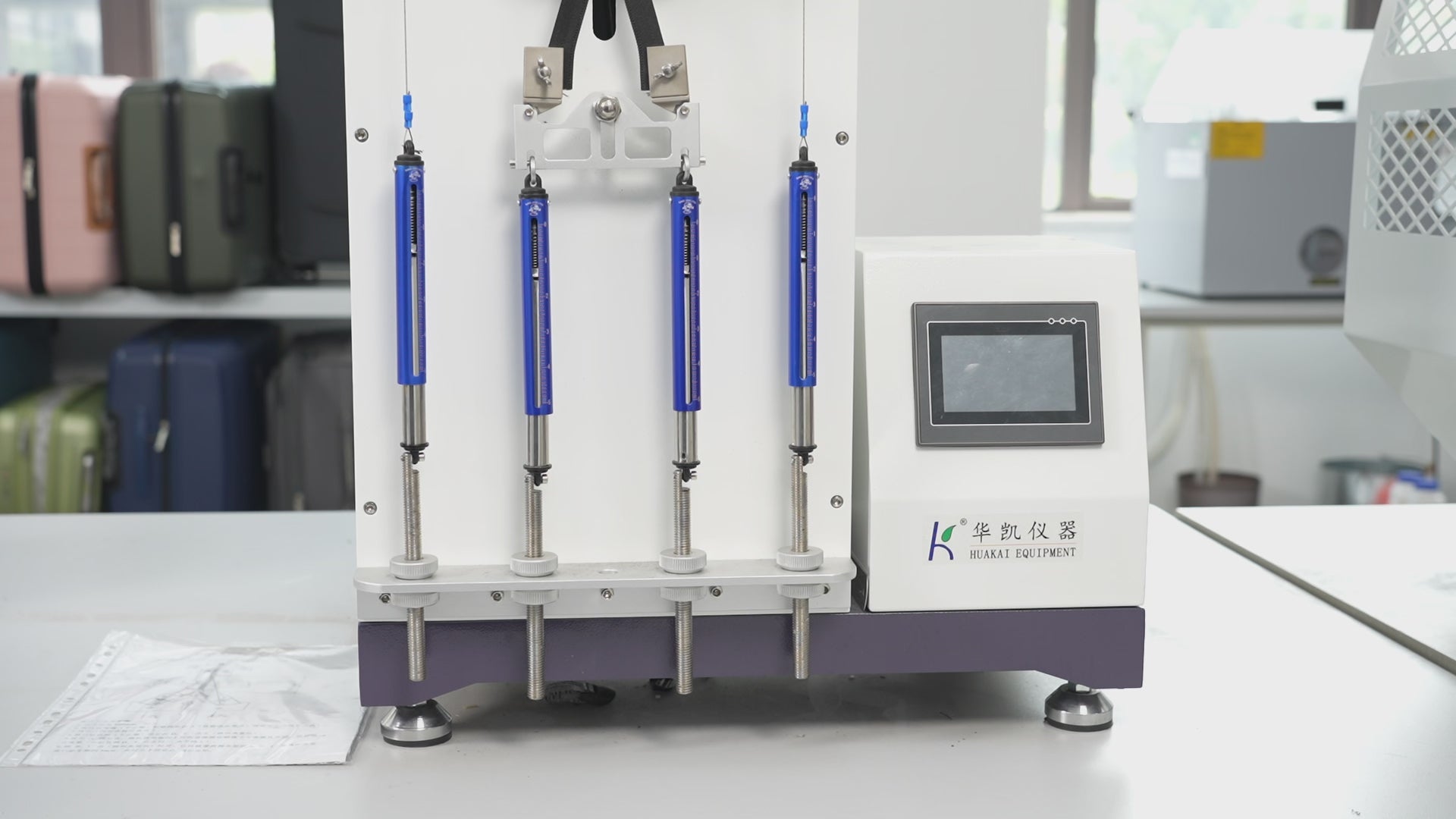

Telescopic Handle Test

Every time you extend and retract that clicky handle, there’s a mechanism doing the work, and over time, that mechanism can wear out.

To make sure ours doesn’t, we tested the telescopic handle through 5,000 full lift and retract cycles. This checks for smooth operation, locking strength, and long term reliability, so it works just as well on your 50th trip as it did on the first.

Handle Strength Test

Sometimes we all get lazy and just grab the suitcase by the extended handle, not the top or side handle like we're supposed to, but that one.

So we tested exactly that, lifting a fully loaded suitcase by the extended telescopic handle 400 times. Why? To make sure the structure holds up, doesn’t buckle, and stays reliable when you end up dragging it by the handle like your life depends on it. In case you are wandering we did also test the top or side handles just as much.

Zipper Stress Test

Overpacking happens... we’re not judging. But straining the zippers on an overstuffed suitcase? That’s a real durability test. To make sure our zippers hold up, we open and close them 1,000 times with 2kg of side pulling force, simulating exactly what happens when your bag’s full to the brim.

Because a broken zipper mid trip is straight up nightmare fuel.

*Applies to certain product lines, please check product page for full details.